What are the mainstream models of stainless steel resistors?

What are the Mainstream Models of Stainless Steel Resistors?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various materials used to manufacture resistors, stainless steel has gained popularity due to its unique properties. This blog post will explore the mainstream models of stainless steel resistors, their applications, and the advantages they offer in electronic circuits.

II. Understanding Resistors

A. Basic Principles of Resistance

At the heart of every resistor is the principle of resistance, which is defined as the opposition to the flow of electric current. According to Ohm's Law, the relationship between voltage (V), current (I), and resistance (R) is expressed as V = I × R. This fundamental equation is essential for understanding how resistors function in electronic circuits.

Resistors come in various types, including fixed, variable, and specialty resistors. Each type serves a specific purpose, from limiting current to dividing voltage and conditioning signals.

B. Role of Resistors in Electronic Applications

Resistors are integral to electronic applications for several reasons:

1. **Current Limiting**: Resistors prevent excessive current from flowing through components, protecting sensitive devices from damage.

2. **Voltage Division**: By using resistors in series, voltage can be divided among components, allowing for precise voltage levels required by different parts of a circuit.

3. **Signal Conditioning**: Resistors help shape and modify signals, ensuring that they meet the necessary specifications for further processing.

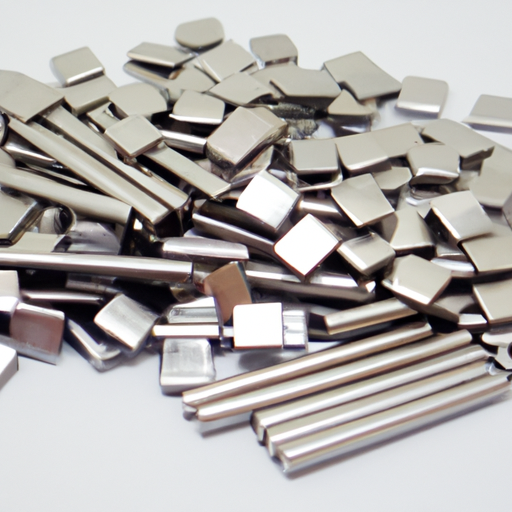

III. Stainless Steel as a Material for Resistors

A. Properties of Stainless Steel

Stainless steel is an alloy known for its corrosion resistance, thermal stability, and mechanical strength. These properties make it an excellent choice for manufacturing resistors, especially in demanding environments.

1. **Corrosion Resistance**: Stainless steel resists oxidation and corrosion, ensuring longevity and reliability in various applications.

2. **Thermal Stability**: It can withstand high temperatures without degrading, making it suitable for high-power applications.

3. **Mechanical Strength**: Stainless steel's robustness allows it to endure physical stress, which is essential for resistors used in industrial settings.

B. Advantages of Using Stainless Steel in Resistors

The use of stainless steel in resistors offers several advantages:

1. **Durability and Longevity**: Stainless steel resistors have a longer lifespan compared to those made from other materials, reducing the need for frequent replacements.

2. **Performance in Harsh Environments**: Their resistance to corrosion and temperature fluctuations makes them ideal for use in harsh industrial environments.

3. **Aesthetic Appeal**: Stainless steel has a sleek, modern appearance, making it suitable for consumer electronics where aesthetics matter.

IV. Mainstream Models of Stainless Steel Resistors

A. Wirewound Resistors

Wirewound resistors are constructed by winding a metal wire, typically made of stainless steel, around a ceramic or fiberglass core. This design allows for high power ratings and excellent heat dissipation.

Applications: Commonly used in power electronics, audio equipment, and industrial applications.

Performance Characteristics: Wirewound resistors offer high precision and stability, with tolerances as low as 0.1%.

Popular Manufacturers and Models: Notable manufacturers include Vishay, Ohmite, and Bourns, with models like the Vishay WSL and Ohmite 50W series.

B. Thin Film Resistors

Thin film resistors are made by depositing a thin layer of resistive material onto a substrate, often using stainless steel as the base material. This construction allows for precise control over resistance values.

Applications: Widely used in precision measurement devices, medical equipment, and telecommunications.

Performance Characteristics: Thin film resistors offer excellent temperature stability and low noise, with tolerances as low as 0.01%.

Popular Manufacturers and Models: Manufacturers like Yageo and Panasonic produce thin film resistors, with models such as the Yageo MFR series.

C. Thick Film Resistors

Thick film resistors are created by screen-printing a thick layer of resistive paste onto a substrate, which can include stainless steel. This method is cost-effective and allows for mass production.

Applications: Commonly found in consumer electronics, automotive applications, and industrial controls.

Performance Characteristics: Thick film resistors provide good stability and are available in a wide range of resistance values.

Popular Manufacturers and Models: Manufacturers like Vishay and KOA produce thick film resistors, with models such as the Vishay CRG series.

D. Metal Film Resistors

Metal film resistors are made by depositing a thin layer of metal onto a ceramic substrate. Stainless steel can be used in the construction to enhance durability.

Applications: Used in precision applications, including audio equipment and instrumentation.

Performance Characteristics: Metal film resistors offer low noise and high stability, with tolerances as low as 0.1%.

Popular Manufacturers and Models: Manufacturers like Bourns and Vishay produce metal film resistors, with models such as the Bourns 3300 series.

V. Comparison of Stainless Steel Resistor Models

A. Performance Metrics

When comparing stainless steel resistor models, several performance metrics are essential:

1. **Tolerance and Accuracy**: Thin film resistors generally offer the highest accuracy, while wirewound resistors provide excellent stability.

2. **Temperature Coefficient**: Thin film resistors have the lowest temperature coefficient, making them ideal for precision applications.

3. **Power Rating**: Wirewound resistors typically have the highest power ratings, suitable for high-power applications.

B. Cost Considerations

Cost can vary significantly among different resistor types. Wirewound resistors tend to be more expensive due to their construction, while thick film resistors are generally more cost-effective for mass production.

C. Suitability for Different Applications

The choice of resistor model depends on the specific application requirements. For high-precision applications, thin film resistors are preferred, while wirewound resistors are ideal for high-power scenarios.

VI. Applications of Stainless Steel Resistors

A. Industrial Applications

Stainless steel resistors are widely used in industrial applications, including:

1. **Automation and Control Systems**: Resistors are essential for controlling current and voltage in automated systems.

2. **Power Electronics**: High-power applications benefit from the durability and performance of stainless steel resistors.

B. Consumer Electronics

In consumer electronics, stainless steel resistors are found in:

1. **Audio Equipment**: High-fidelity audio systems require precise resistors for optimal performance.

2. **Home Appliances**: Resistors are used in various appliances to ensure safe and efficient operation.

C. Medical Devices

Stainless steel resistors play a critical role in medical devices, including:

1. **Diagnostic Equipment**: Precision resistors are essential for accurate measurements in diagnostic tools.

2. **Monitoring Systems**: Resistors help ensure reliable performance in patient monitoring systems.

VII. Future Trends in Stainless Steel Resistors

A. Innovations in Materials and Technology

The future of stainless steel resistors will likely see innovations in materials and manufacturing processes, leading to even better performance and reliability.

B. Increasing Demand for High-Performance Resistors

As technology advances, the demand for high-performance resistors will continue to grow, particularly in sectors like telecommunications and medical devices.

C. Environmental Considerations and Sustainability

With increasing awareness of environmental issues, manufacturers are focusing on sustainable practices, including the use of recyclable materials and energy-efficient production methods.

VIII. Conclusion

Stainless steel resistors are an essential component in modern electronics, offering durability, precision, and performance in various applications. From wirewound to thin film models, each type has its unique advantages and is suited for specific uses. As technology continues to evolve, the future of stainless steel resistors looks promising, with innovations that will enhance their functionality and sustainability.

IX. References

1. Vishay Intertechnology. (n.d.). Resistor Types and Applications. Retrieved from [Vishay](https://www.vishay.com)

2. Ohmite Manufacturing Company. (n.d.). Wirewound Resistors. Retrieved from [Ohmite](https://www.ohmite.com)

3. Yageo Corporation. (n.d.). Thin Film Resistors. Retrieved from [Yageo](https://www.yageo.com)

4. Bourns, Inc. (n.d.). Metal Film Resistors. Retrieved from [Bourns](https://www.bourns.com)

5. KOA Speer Electronics. (n.d.). Thick Film Resistors. Retrieved from [KOA](https://www.koaspeer.com)

This blog post provides a comprehensive overview of stainless steel resistors, their types, applications, and future trends, making it a valuable resource for anyone interested in electronics.