What are the product standards for the role of resistors?

What are the Product Standards for the Role of Resistors?

I. Introduction

Resistors are fundamental components in electronic circuits, serving as the backbone for controlling current flow and voltage levels. They are passive devices that resist the flow of electric current, allowing engineers to design circuits that perform specific functions. The importance of resistors cannot be overstated; they are used in virtually every electronic device, from simple household appliances to complex computing systems. Given their critical role, adherence to product standards is essential to ensure safety, reliability, and performance in electronic applications. This blog post will explore the product standards for resistors, their significance, and the key parameters that define their performance.

II. Understanding Resistors

A. Basic Principles of Resistance

At the heart of resistor functionality lies Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship is expressed mathematically as:

\[ V = I \times R \]

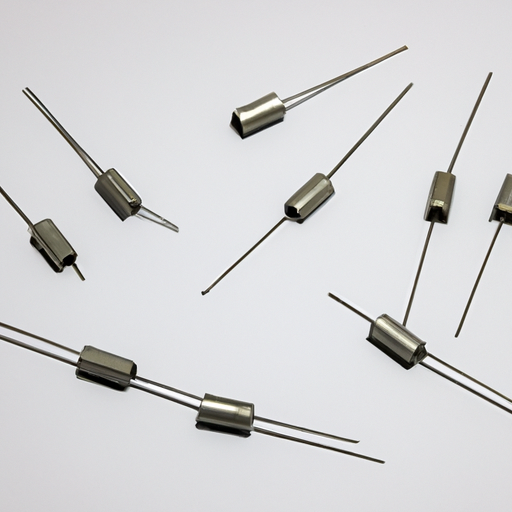

Resistors come in various types, including fixed resistors, which have a constant resistance value, and variable resistors, such as potentiometers, which allow for adjustable resistance. Each type serves different applications in electronic devices.

B. Applications of Resistors in Electronic Devices

Resistors play several critical roles in electronic circuits:

1. **Current Limiting**: Resistors are often used to limit the amount of current flowing through a circuit, protecting sensitive components from damage.

2. **Voltage Division**: By using resistors in series, engineers can create voltage dividers that provide specific voltage levels for different parts of a circuit.

3. **Signal Conditioning**: Resistors are used in conjunction with capacitors and inductors to filter signals, shaping the frequency response of circuits.

III. Product Standards for Resistors

A. International Standards Organizations

To ensure the quality and reliability of resistors, several international standards organizations establish guidelines and specifications. Key organizations include:

1. **International Electrotechnical Commission (IEC)**: Develops international standards for electrical and electronic technologies.

2. **Institute of Electrical and Electronics Engineers (IEEE)**: Focuses on advancing technology for humanity, including standards for electronic components.

3. **American National Standards Institute (ANSI)**: Oversees the development of voluntary consensus standards for products, services, processes, and systems in the U.S.

B. Key Standards Relevant to Resistors

Several key standards specifically address resistors:

1. **IEC 60115**: This standard outlines the requirements for fixed resistors used in electronic equipment, including performance, reliability, and safety criteria.

2. **IEC 62032**: This standard specifies the requirements for resistors used in electronic circuits, focusing on their electrical characteristics and environmental performance.

3. **MIL-PRF-55182**: This military specification covers resistors designed for military applications, ensuring they meet stringent performance and reliability standards.

C. Importance of Compliance with Standards

Compliance with these standards is crucial for several reasons:

1. **Safety Considerations**: Adhering to established standards helps prevent electrical hazards and ensures that resistors can operate safely within specified limits.

2. **Performance Reliability**: Standards provide guidelines for performance metrics, ensuring that resistors function as intended over their lifespan.

3. **Interoperability**: Standardization facilitates compatibility between different components and systems, allowing for seamless integration in complex electronic designs.

IV. Key Parameters and Specifications

A. Resistance Value and Tolerance

The resistance value is a fundamental specification of a resistor, indicating how much it resists current flow. Tolerance levels, expressed as a percentage, indicate the allowable deviation from the nominal resistance value. For example, a resistor with a nominal value of 100 ohms and a tolerance of ±5% can have an actual resistance between 95 and 105 ohms. Understanding these parameters is essential for ensuring that resistors meet the requirements of specific applications.

B. Power Rating

The power rating of a resistor indicates the maximum amount of power it can dissipate without overheating. It is typically expressed in watts (W). Factors affecting power rating include the resistor's physical size, material, and construction. Exceeding the power rating can lead to resistor failure, making it a critical specification in circuit design.

C. Temperature Coefficient

The temperature coefficient measures how much a resistor's resistance changes with temperature. It is expressed in parts per million per degree Celsius (ppm/°C). A low temperature coefficient is desirable for precision applications, as it indicates that the resistor's performance will remain stable across a range of temperatures.

D. Voltage Rating

The voltage rating indicates the maximum voltage that can be applied across a resistor without risking breakdown or failure. It is essential to consider the voltage rating in circuit design to prevent damage to the resistor and ensure reliable operation.

V. Testing and Quality Assurance

A. Testing Methods for Resistors

To ensure that resistors meet specified standards, various testing methods are employed:

1. **Resistance Measurement Techniques**: These include using ohmmeters or precision resistance bridges to measure the actual resistance value.

2. **Power Rating Tests**: Resistors are subjected to power tests to verify that they can handle their rated power without overheating.

3. **Environmental Testing**: Resistors may undergo environmental tests to assess their performance under different temperature and humidity conditions.

B. Quality Assurance Processes

Quality assurance is vital in resistor manufacturing. Key processes include:

1. **Manufacturing Quality Control**: Implementing strict quality control measures during production to ensure consistency and reliability.

2. **Certification and Compliance Testing**: Conducting tests to verify compliance with relevant standards and obtaining certifications from recognized organizations.

3. **Role of Third-Party Testing Organizations**: Independent testing organizations can provide unbiased assessments of resistor performance and compliance.

VI. Emerging Trends and Innovations

A. Advances in Resistor Technology

Recent advancements in resistor technology have led to the development of new types of resistors, such as thin-film and thick-film resistors, which offer improved performance and miniaturization. Surface mount technology (SMT) has also gained popularity, allowing for smaller and more efficient circuit designs.

B. Impact of Digitalization on Resistor Standards

The rise of digitalization and the Internet of Things (IoT) has introduced new challenges and opportunities for resistor standards. Smart resistors, which can adapt their resistance based on environmental conditions or circuit requirements, are becoming increasingly relevant. Integration with other electronic components is also driving the need for updated standards to ensure compatibility and performance.

VII. Conclusion

In conclusion, product standards for resistors play a crucial role in ensuring the safety, reliability, and performance of electronic devices. As technology continues to evolve, so too will the standards governing resistors, adapting to new applications and innovations. Understanding these standards and the key parameters that define resistor performance is essential for engineers and designers in the electronics industry. As we look to the future, the role of resistors in modern electronics will remain vital, underpinning the functionality of countless devices that shape our daily lives.

VIII. References

1. International Electrotechnical Commission (IEC). (n.d.). IEC 60115 - Fixed resistors for use in electronic equipment.

2. International Electrotechnical Commission (IEC). (n.d.). IEC 62032 - Resistors for use in electronic circuits.

3. U.S. Department of Defense. (n.d.). MIL-PRF-55182 - Resistors for military applications.

4. Institute of Electrical and Electronics Engineers (IEEE). (n.d.). IEEE Standards Association.

5. American National Standards Institute (ANSI). (n.d.). ANSI Standards Overview.

This blog post provides a comprehensive overview of the product standards for resistors, highlighting their importance in electronic design and the evolving landscape of technology.